Production Practices

Discover how our innovative production practices and cutting-edge technologies are transforming the way we manufacture products that are both high-quality and environmentally responsible.

We work with our trusted and certified local European manufacturers to adopt lean manufacturing principles, to implement recycling and waste reduction systems, to use green energy and to reduce transportation of goods.

These initiatives all contribute to a greener production and reduce pollution greatly compared to traditional manufacturing practices.

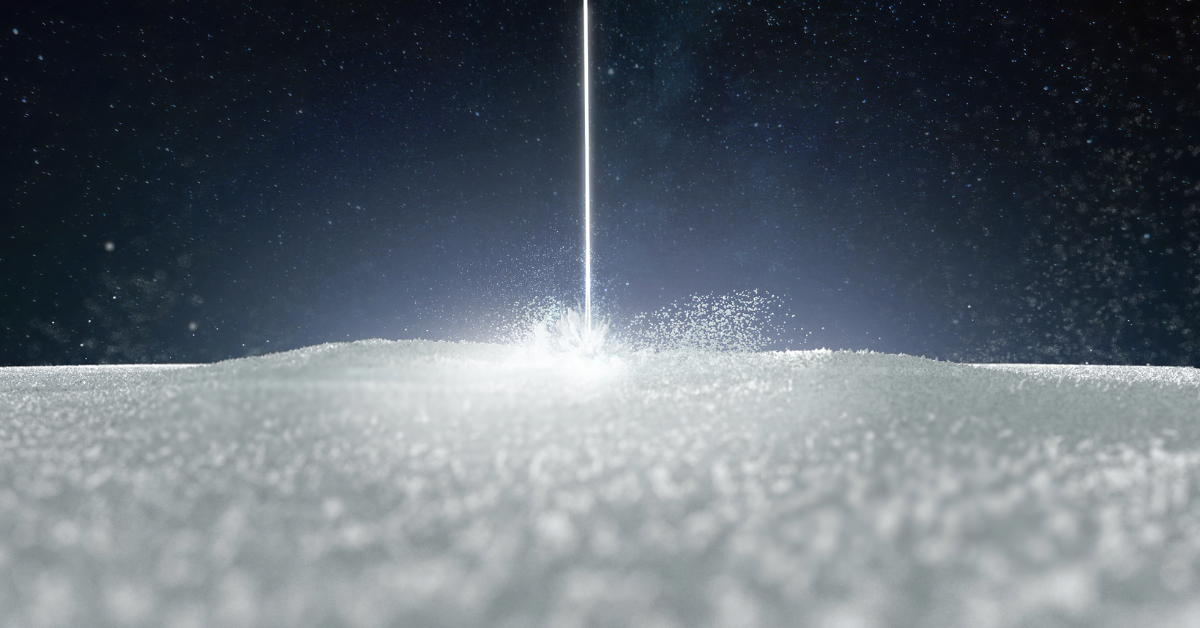

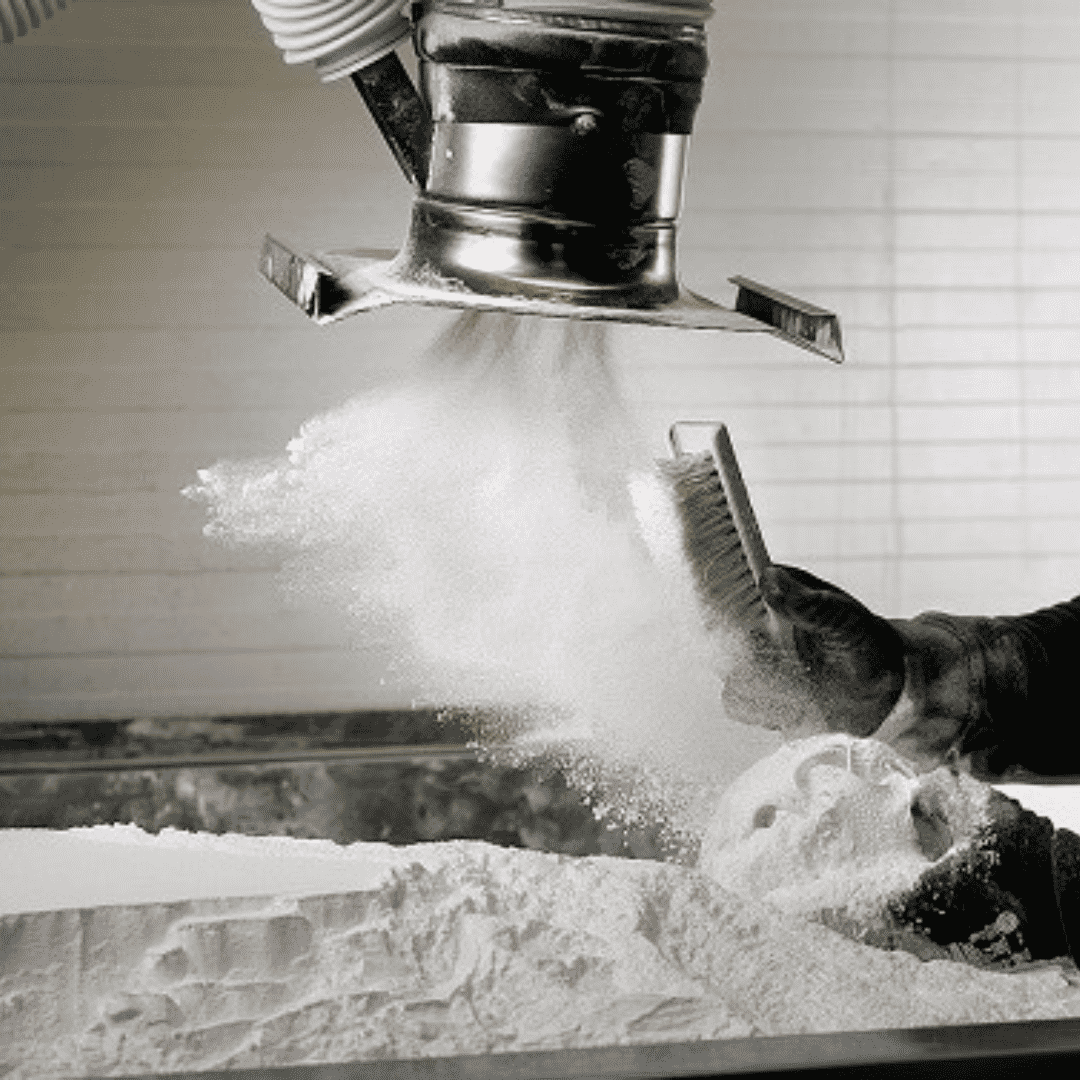

SLS 3D Printed Frame

For our frame we use Selective Laser Sintering (SLS) 3D printing technology, which is an additive manufacturing process that uses a laser to sinter powdered materials, into a solid object.

The SLS process begins by spreading a thin layer of powdered PA11 material onto a build platform, the compact power is melted by a laser causing it to fuse together in our shapes. The laser then selectively fuses new layers onto the previous ones, and the process repeats layer by layer until our parts are complete. It is cooled to solid hard material and our parts are finished with surface treatments to make the frame weather resistant and durable.

This process provides less waste as excess powder can be reused, it is a small batch production which avoids large-scale production runs and excess inventory, it is more energy efficient and it is all done locally to reduce transportation emissions.

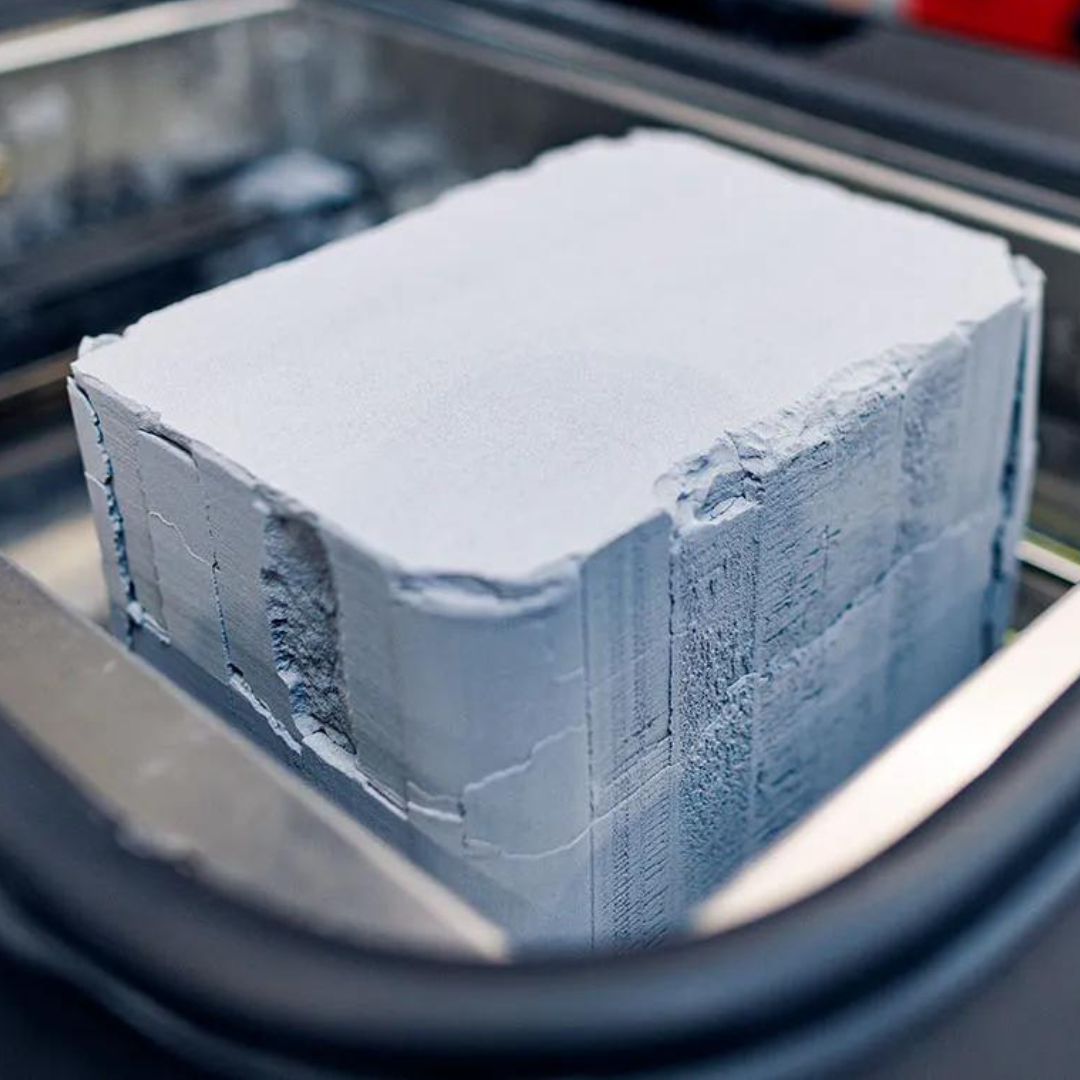

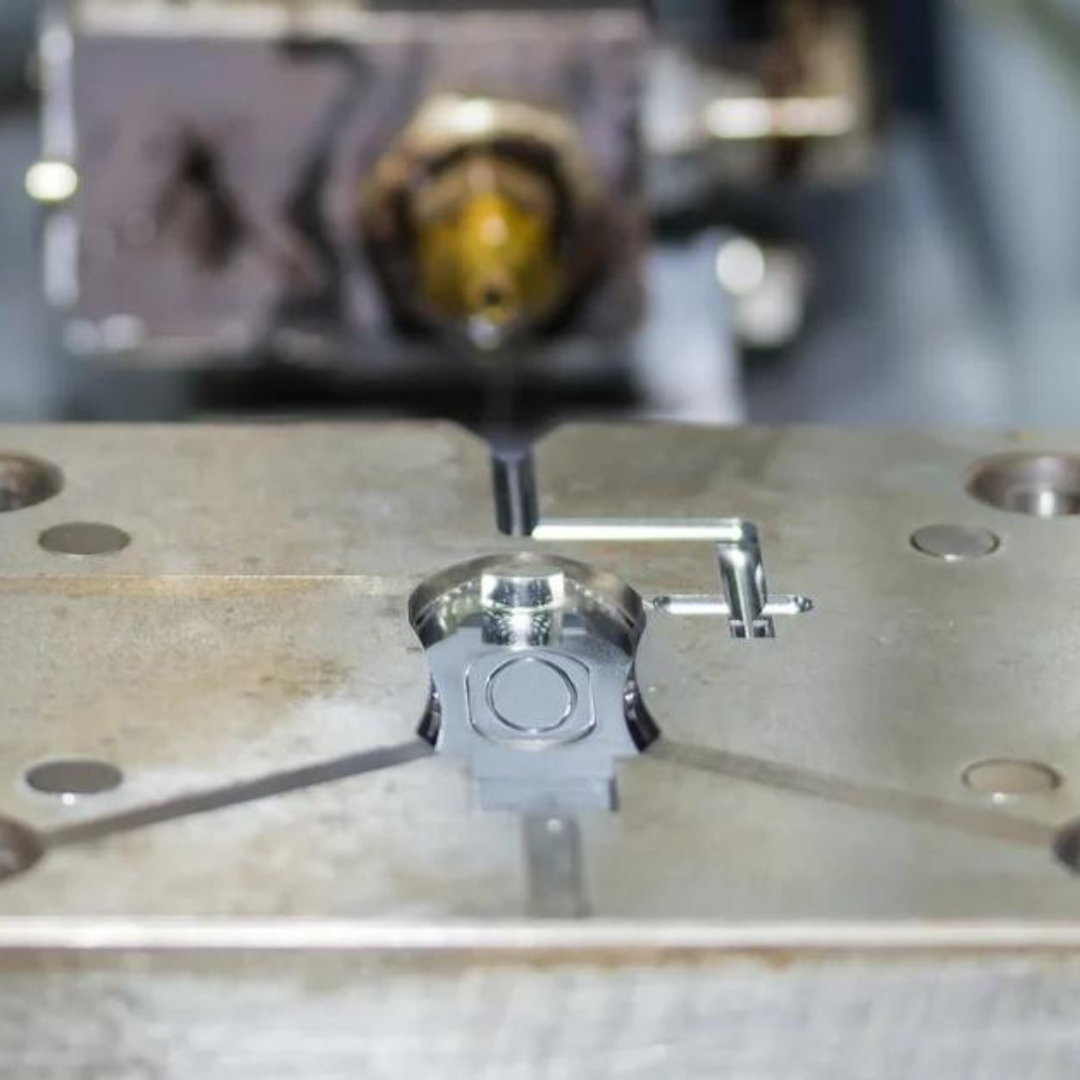

Injection Molded Rubber

For our rubber nosepads we use traditional injection molding production.

Liquid silicone rubber (LSR) injection molding involves extraction the highly viscous LSR from drums or pails using a dosing unit and injecting it into a closed mold in the press.

The mold is then heated, and the heat combined with pressure applied to the LSR results in the rubber becoming a solid part.

Liquid injection molding provides the most efficient and economically viable process using LSR.

Mass Balance Lens Approach

Our polyamid lenses are made of 39% bio-based material using the mass balance production approach. It involves the mixing of sustainably sourced materials with conventional materials in the production process.

Our certified raw bio-based materials are collected, monomers and polymers are made through a chemical transformation and mixing of bio-based and fossil-based materials, and finally the monomers and polymers are used in the manufacturing of our polyamid nylon lenses.

This approach ensures that the overall environmental impact of our lenses are reduced by up to 50% compared to the current standard production processes and products.

RPET Accessories Production

RPET, also known as recycled PET fabric, is made from recycled plastic bottles or other post-consumer PET products.

It is made by collecting plastic products from recycling programs or waste management systems, the PET items are cleaned and shredded into flakes, after the flakes are heated and extruded through fine openings to create long filaments or fibers, which are spun into yarns, then the yarns are woven together to create our RPET fabric that is finished into our cleaning cloth and pouch.

The use of RPET for our accessories helps reduce waste, conserve resources, and decrease the demand for new raw materials.

Final Assembling

Our sunglasses are assembled by hand locally in Denmark, which reduce the need for transportation of goods from our European suppliers. It also minimize the use of machines and electricity compared to automatic assembling processes.

Finally, it let's us assess the quality of each pair of sunglasses before they leave our warehouse to make sure they are in perfect condition.

Production Certifications

-

ISO 14001

-

ISO 9001

-

REDcert2

-

Back to Strategy and Goals

Click here -

Continue to Materials

Click here